How do I choose the right CO2 laser focusing lens for my laser?

Споделете

How do I choose the right CO2 laser focusing lens for my laser?

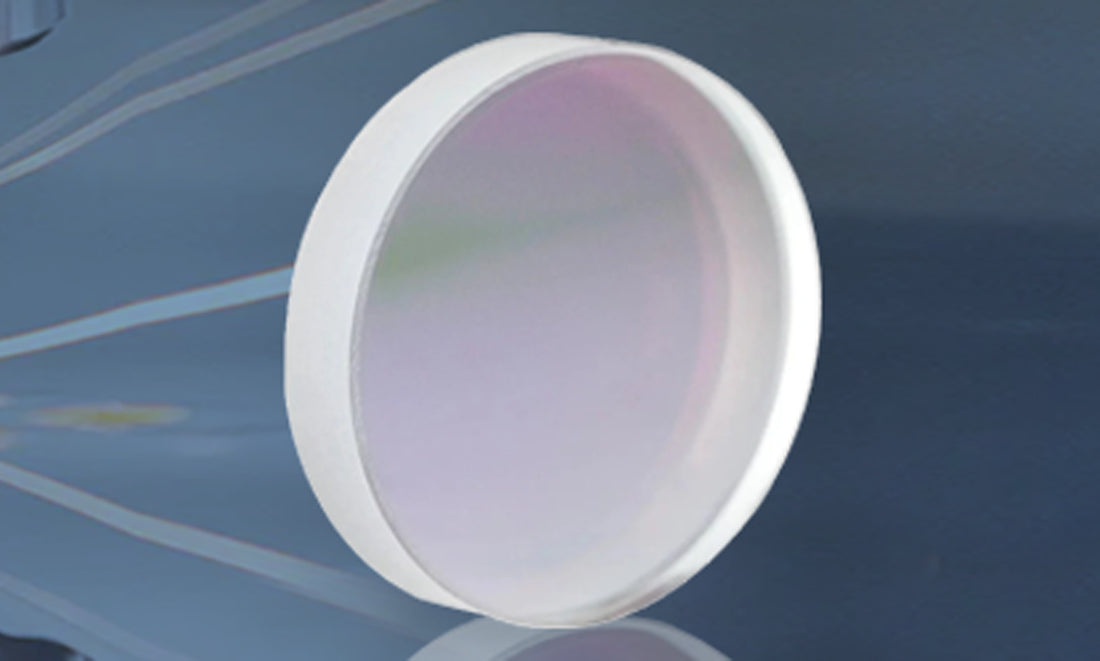

CO2 laser systems are widely used for cutting, engraving, and marking applications, and the focusing lens plays a critical role in determining the system’s performance. Selecting the correct lens for your specific application can significantly enhance processing quality, efficiency, and even the lifespan of your laser system. This blog will help you understand what a focusing lens does, the types of lenses suited for different projects, and how to choose the right one for your needs.

What Does a Laser Focusing Lens Do?

The primary function of a CO2 laser focusing lens is to concentrate the divergent laser beam into a small focal point, creating a high-density energy area. This concentrated energy allows the laser to cut or engrave materials with precision.

Key roles of the focusing lens include:

- Improving accuracy: A well-focused laser beam produces clean and smooth edges.

- Controlling depth: The position of the focal point determines the depth of the laser’s effect on the material.

- Enhancing efficiency: Proper lens selection minimizes heat dispersion, increasing processing speed and energy efficiency.

Which Lens Is Best for Which Type of Project?

The lens focal length, typically measured in inches, determines its suitability for various applications. Here’s a breakdown:

-

Short Focal Length Lenses (1.5 inches or less)

- Features: Small laser spot size, high energy density.

-

Best for:

- Detailed engraving such as fine text, intricate patterns, or small designs.

- Cutting thin materials like paper, thin wood, or plastics.

-

Advantages:

- High precision for fine detail.

-

Drawbacks:

- Shallow depth of focus, not ideal for thicker materials.

-

Medium Focal Length Lenses (2 inches)

- Features: A balance between precision and versatility.

-

Best for:

- General-purpose cutting and engraving.

- Medium-thickness materials like acrylic and wood.

-

Advantages:

- Moderate depth of focus and spot size, suitable for a wide range of applications.

-

Drawbacks:

- Less effective for ultra-fine detail or very thick materials.

-

Long Focal Length Lenses (2.5 inches or more)

- Features: Larger laser spot size, longer depth of focus.

-

Best for:

- Cutting thick materials like thick acrylic, wood, or metal.

- Engraving large designs where edge quality is critical.

-

Advantages:

- Deep focus ensures consistent penetration in thick materials.

-

Drawbacks:

- Larger spot size limits its suitability for fine engraving.

Which Laser Focus Lens Is Best for My Application?

Choosing the right lens depends on your specific needs and the material you are working with. Here are some recommendations:

-

For Fine Engraving (e.g., signs, customized gifts):

- Recommended Lens: Short focal length lens (1.5 inches).

- Why: Small spot size delivers high detail for intricate designs.

-

For General-Purpose Cutting and Engraving (e.g., furniture parts, decorations):

- Recommended Lens: Medium focal length lens (2 inches).

- Why: Suitable for most materials and tasks, offering a balance of precision and flexibility.

-

For Cutting Thick Materials (e.g., architectural models, thick metal sheets):

- Recommended Lens: Long focal length lens (2.5 inches or more).

- Why: Deep focus ensures smooth and clean cuts through thick materials.

-

For Laser Marking (e.g., product serial numbers, QR codes):

- Recommended Lens: Short or medium focal length lens, depending on marking area size.

- Why: Ensures focused, clear markings.

Important Considerations

When selecting and using a CO2 laser focusing lens, keep the following in mind:

- Compatibility: Ensure the lens diameter and focal length match your laser head specifications.

-

Lens Material:

- ZnSe (Zinc Selenide): Excellent light transmission, ideal for high-precision work.

- GaAs (Gallium Arsenide): More durable, suited for harsh environments.

- Maintenance: Regularly clean the lens surface to prevent dust and debris from affecting laser performance.

- Working Environment: Protect the lens from extreme heat, moisture, and dust to prolong its lifespan.

- Budget: High-quality lenses are more expensive but deliver better durability and performance. Choose one that offers the best balance of cost and functionality for your needs.

Conclusion

Selecting the right CO2 laser focusing lens requires careful consideration of your application type, material properties, and precision requirements. Short focal length lenses excel at fine engraving, medium lenses are ideal for versatile applications, and long focal length lenses are best for cutting thick materials. By understanding the roles and characteristics of each lens type, you can make an informed decision and optimize your laser system’s performance.

If you have any questions or need further assistance in selecting a CO2 laser focusing lens, feel free to leave a comment or get in touch with us!