What is the best laser nozzle to choose for laser cutting?

Share

What is the best laser nozzle to choose for laser cutting?

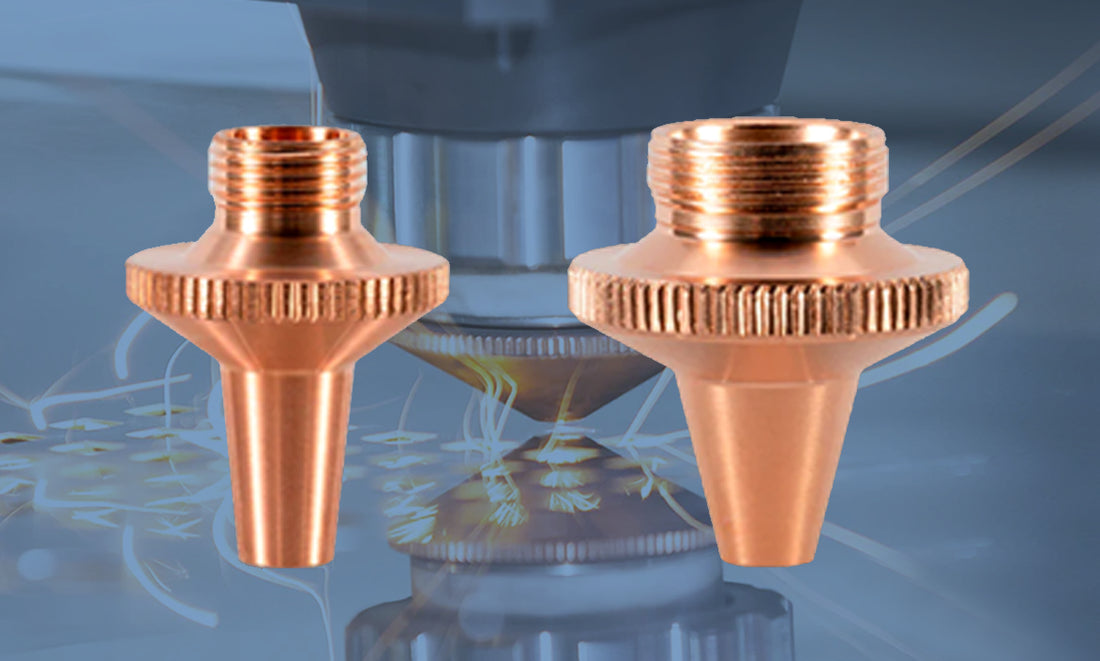

Laser cutting is a versatile manufacturing process that relies on precision and efficiency. One crucial yet often overlooked component in this process is the nozzle. The nozzle plays a vital role in directing assist gas, controlling the cutting area, and ensuring the quality of the cut. In this blog, we'll explore the types of nozzles used in laser cutting and their specific applications.

Why is the Nozzle Important in Laser Cutting?

The nozzle is located at the bottom of the laser cutting head, positioned just above the workpiece. Its primary functions include:

- Guiding the Assist Gas: Assist gases, such as oxygen, nitrogen, or compressed air, are directed through the nozzle to remove molten material from the cutting area.

- Protecting the Lens: The nozzle helps shield the cutting head's optics from debris and contaminants, ensuring consistent performance.

- Precision Focus: It defines the gas flow and beam alignment, influencing the precision and quality of the cut.

Types of Laser Nozzles Used in Laser Cutting

There are several types of nozzles, each designed for specific cutting requirements and materials. The most common types include:

-

- Applications: Typically used for cutting mild steel.

- Assist Gas: Oxygen is commonly used with this nozzle to enhance the cutting process.

- Benefits: Produces a clean cut with minimal slag due to the oxidizing effect of oxygen.

-

- Applications: Ideal for high-precision cuts on stainless steel or aluminum.

- Assist Gas: Nitrogen is frequently used to avoid oxidation and discoloration.

- Benefits: Provides a smooth, burr-free finish and is suitable for aesthetic cuts.

-

Conical Nozzles

- Applications: Used for intricate or detailed cutting tasks.

- Features: Narrow nozzle tips help maintain a focused gas stream.

- Advantages: Ensures high precision in tight spaces.

-

Parallel Nozzles

- Applications: Common in thicker material cutting.

- Benefits: Uniform gas distribution allows for deeper and more efficient cuts.

Factors to Consider When Choosing a Laser Nozzle

Choosing the right nozzle depends on several factors:

- Material Type: Different materials require specific assist gases and nozzle designs.

- Cutting Thickness: Larger nozzles are better for thick materials, while smaller ones suit thin materials.

- Desired Finish: A burr-free, smooth finish may necessitate a specific nozzle and gas combination.

- Power of the Laser: High-powered lasers often require nozzles capable of withstanding intense heat.

Nozzle Maintenance Tips

To ensure optimal performance, regular maintenance of the nozzle is essential:

- Clean the nozzle frequently to prevent debris buildup.

- Check for wear and tear; even small imperfections can affect cut quality.

- Replace damaged or worn-out nozzles promptly.

Conclusion

The nozzle in a laser cutting machine is a small yet critical component that directly impacts the efficiency, quality, and precision of the cutting process. By understanding the different types of nozzles and their applications, you can enhance your laser cutting operations and achieve superior results.

Whether you're working with steel, aluminum, or other materials, selecting the right nozzle is key to success in laser cutting. Keep your nozzles in top shape and experiment with various configurations to find the perfect setup for your needs.

Feel free to share your experiences or ask questions about laser cutting nozzles in the comments below!