Laser Spare Parts Shop

Фокусировочная линза лазера BMLaser II-VI CVD ZnSe CO2

Фокусировочная линза лазера BMLaser II-VI CVD ZnSe CO2

Не удалось загрузить сведения о доступности самовывоза

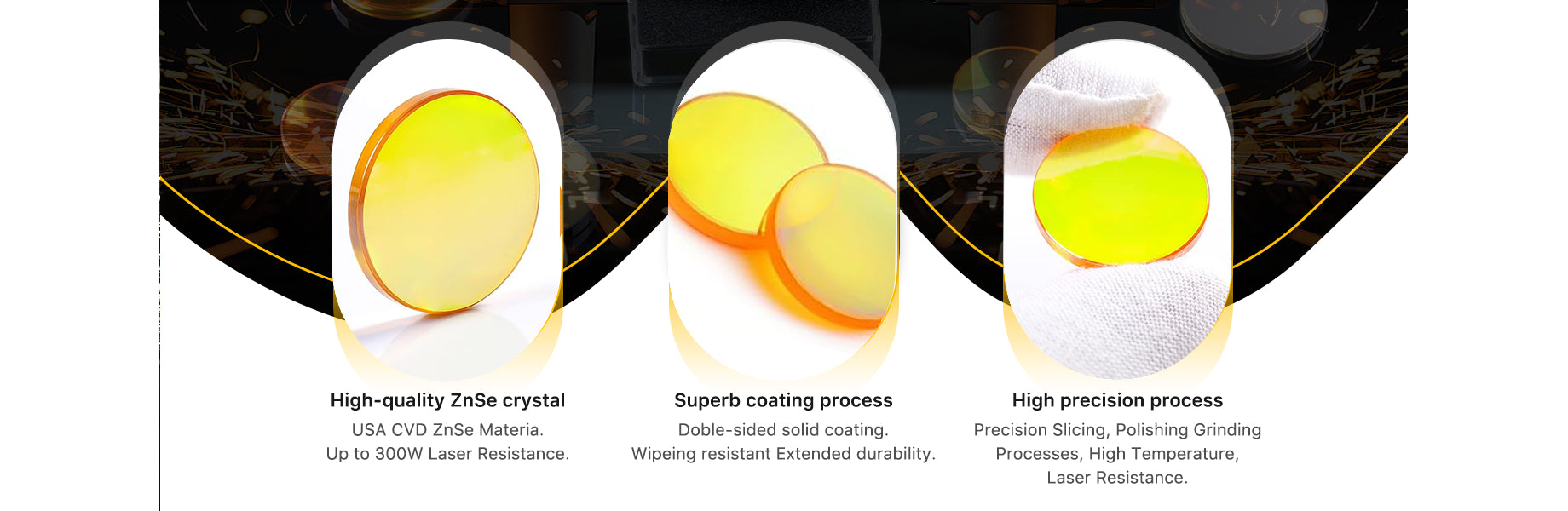

🌍 Официальный контроль качества BMLaser: 100% новая продукция, напрямую с завода.

🏭 Производственная линия: Лазерные инструменты и лазерные станки.

💁 Поддержка специалистов: безопасные платежи; пожизненная онлайн-техническая поддержка.

🚢 Доставка по всему миру: предлагаем доставку по всему миру, экспресс-доставку от двери до двери.

⚙️ Сопутствующие товары: лазерная сварка, лазерная гравировка, станки для лазерной резки, лазерные инструменты, гибочные прессы, станки с ЧПУ, оборудование для обработки листового металла.

Артикул:

Share

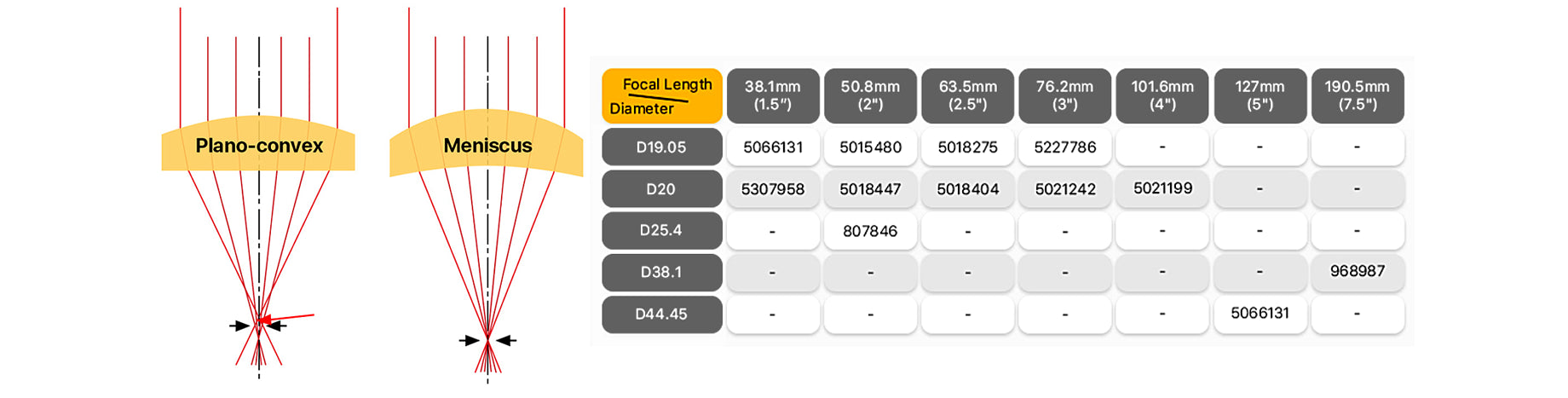

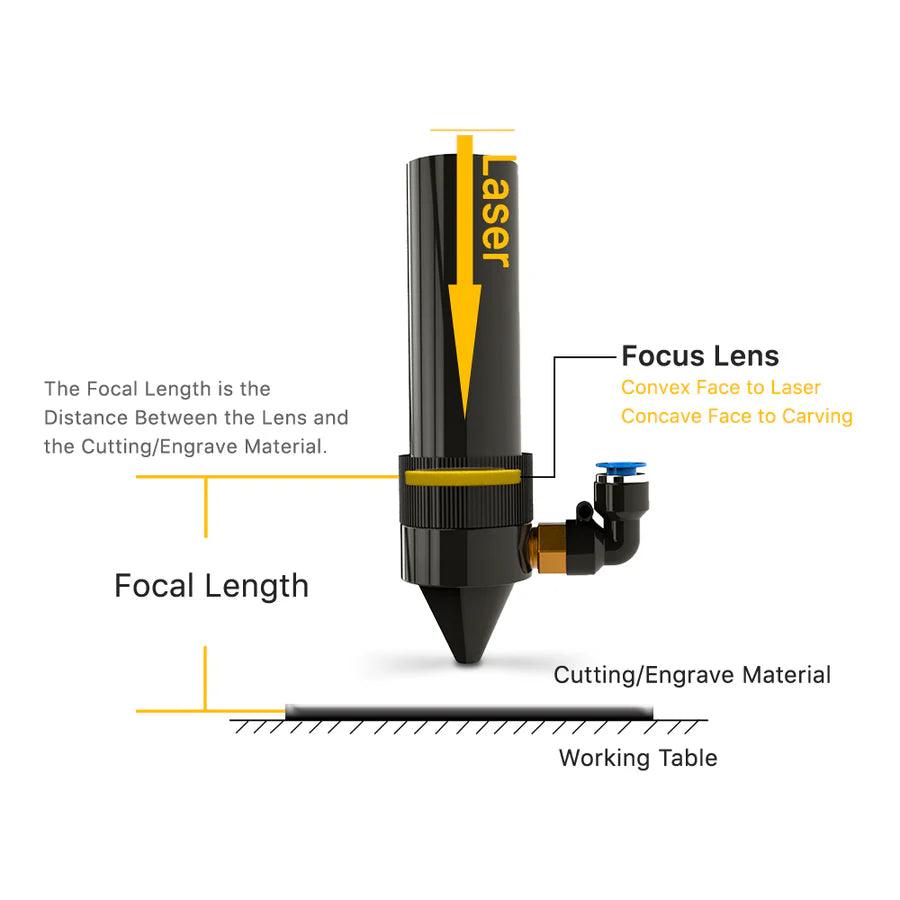

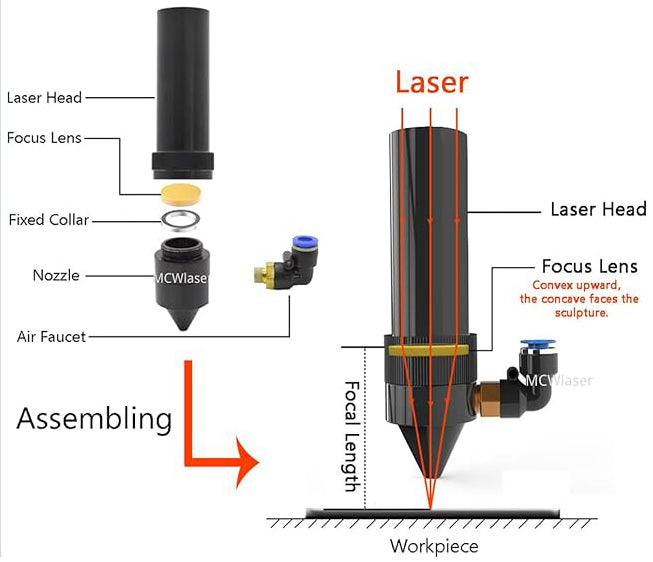

How to determing focal length

The Focal Length is the distance between the lens and the cutting material.

The cutting requirements for different materials vary in terms of focal length. Typically, thinner materials require longer focal lengths, while thicker materials require shorter focal lengths. This is because the position of the focal point affects the focusing depth and diameter of the laser beam.

Cloudray Laser Lens

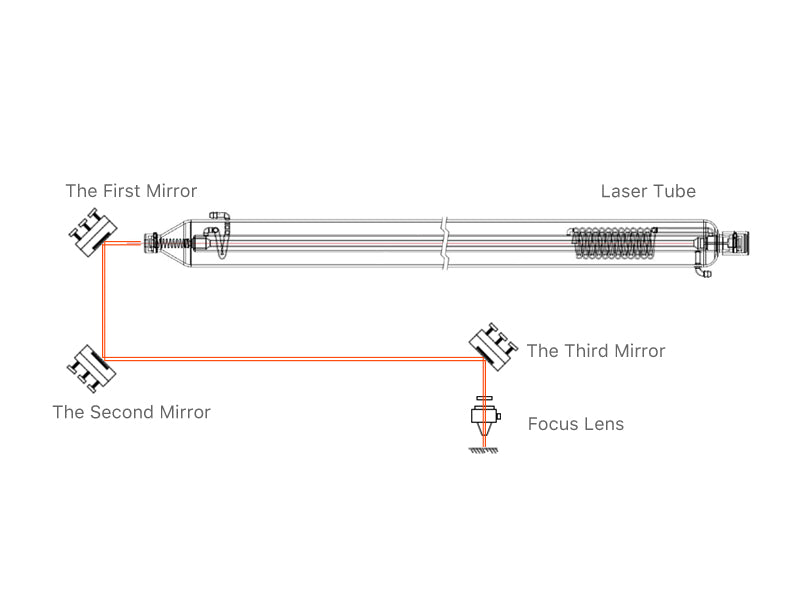

In the CO2 cutting process, the common optical path structure typically includes one focusing lens and two reflecting mirrors.

The focusing lens is located after the output coupling mirror and is primarily used to adjust the direction and shape of the laser, making it as symmetrical as possible, and guiding the laser beam to the subsequent reflecting mirrors.

leaning Instructions

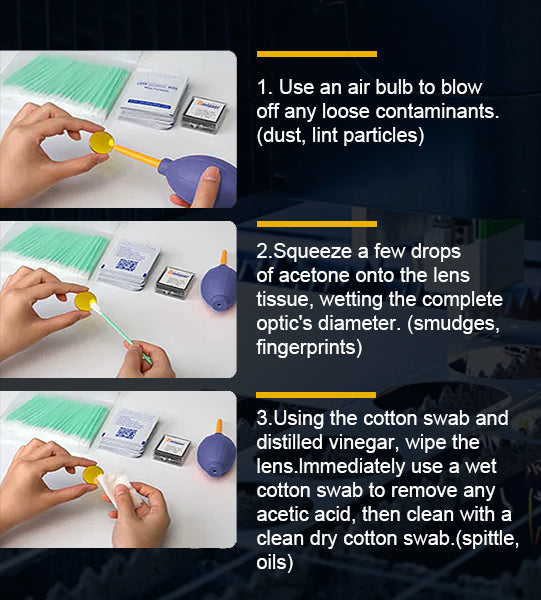

1. Use appropriate cleaning materials: Use gentle cleaning materials such as lens cleaning solution or lens cleaning tissues specifically designed for optical surfaces.

2. Clean in a dust-free environment: Ensure that the cleaning process is carried out in a clean and dust-free environment to prevent particles from getting onto the lens surface during cleaning.

3. Avoid excessive force,Excessive force can cause damage to the lens or misalignment of its optical properties.